Exploring the Top Examples of Large CNC Machines for Global Buyers

In the world of modern manufacturing, the emergence of large CNC machines has revolutionized the way industries approach precision engineering and production efficiency. These powerful machines enable manufacturers to create intricate components and large-scale structures with unmatched accuracy and speed. As global markets continue to evolve, the demand for specialized machinery has surged, leading to an array of large CNC machines designed to meet diverse needs across various sectors.

This blog explores the top examples of large CNC machines available to buyers worldwide, highlighting their unique benefits, features, and applications. By understanding these machines, potential buyers can make informed decisions that enhance productivity and drive innovation in their operations, ultimately transforming their manufacturing capabilities.

The Evolution of Large CNC Machines in the Global Manufacturing Landscape

The global manufacturing landscape has witnessed a significant evolution in large CNC (Computer Numerical Control) machines, driven by advances in technology and increasing demand for precision engineering. According to a report by MarketsandMarkets, the CNC machine market is projected to grow from USD 63.52 billion in 2021 to USD 100.64 billion by 2026, at a compound annual growth rate (CAGR) of 9.5%. This growth underlines the pivotal role that large CNC machines play in enhancing productivity and accuracy in manufacturing processes.

Historically, large CNC machines were primarily used in specialized industries; however, recent innovations have broadened their applications across diverse sectors such as aerospace, automotive, and heavy machinery. The introduction of advanced features like multi-axis machining and automation has not only improved operational efficiency but has also enabled manufacturers to reduce lead times significantly. For instance, a recent study from the Association for Manufacturing Technology indicated that advanced CNC technologies can decrease production time by up to 30%, leading to substantial cost savings and increased competitiveness in the global market. As manufacturing demands continue to evolve, the adaptability and capabilities of large CNC machines will be crucial for companies aiming to thrive in an increasingly competitive environment.

Key Market Players in Large CNC Machinery and Their Innovations

The global CNC machinery market is experiencing significant growth, with forecasts projecting a surge from $101.22 billion in 2025 to an impressive $195.59 billion by 2032, reflecting a robust CAGR of 9.9% during this period. This expansion is driven by numerous innovative players who are continually enhancing their offerings to meet the rising demands of various industries. Notably, companies are integrating advanced technologies such as automation and IoT into their CNC machine designs, positioning themselves as leaders in this competitive market.

Among the key market players, several have emerged as pioneers in bringing innovation to large CNC machines. The metal forming tools segment is also witnessing a substantial rise, with a projected market size increase from $29.41 billion in 2025 to $51.67 billion by 2032, growing at a CAGR of 8.4%. This indicates not only a healthy demand for CNC tools but also an increasing sophistication in manufacturing processes. In regions like Europe, the CNC machine tools market is expected to reach $47.75 billion by 2033, primarily fueled by advancements in German manufacturing technologies, which dominate the market with a share of 32.4%.

Exploring the Top Examples of Large CNC Machines for Global Buyers

| Machine Type | Max Cutting Size | Control System | Spindle Power | Year of Innovation |

|---|---|---|---|---|

| CNC Milling Machine | 2000 x 1000 x 700 mm | Fanuc Control | 30 kW | 2023 |

| CNC Lathe | 1500 mm Length | Siemens Control | 25 kW | 2022 |

| CNC Router | 3000 x 2000 mm | Biesse Control | 20 kW | 2021 |

| 5-Axis CNC Machine | 1000 x 800 x 600 mm | Heidenhain Control | 35 kW | 2020 |

| Plasma Cutting Machine | 4000 x 2000 mm | OMRON Control | 40 kW | 2023 |

Technological Advancements Driving Efficiency in Large CNC Machining

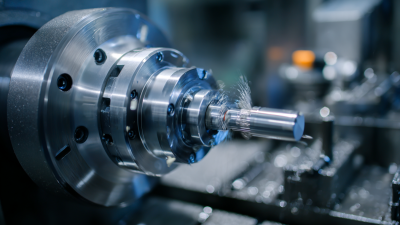

The CNC (Computer Numerical Control) machine market is experiencing a remarkable transformation driven by technological advancements that significantly enhance efficiency in manufacturing. As manufacturers increasingly adopt automation, CNC machines are revolutionizing production processes, allowing for precision machining and streamlined operations. This shift is not merely a trend; it is projected that the CNC machines market will reach USD 170.4 billion by 2033, exhibiting a robust CAGR of 9.80% from 2024 to 2033. Such growth underscores the pivotal role that CNC technology plays in modern manufacturing.

Moreover, the integration of artificial intelligence is further optimizing factory floors, enabling substantial reductions in operational costs and improvements in sustainability. AI-powered systems leverage data analytics to enhance decision-making processes, predict maintenance needs, and increase overall productivity. As digital manufacturing technologies continue to advance, businesses across a diverse range of industries are witnessing unprecedented improvements in efficiency, driving demand for large CNC machines in a competitive global market. With partnerships that push the boundaries of innovation and new market entrants evolving the landscape, the future of CNC machining is poised for remarkable growth and transformation.

Impact of Large CNC Machines on Production Costs and Time Savings

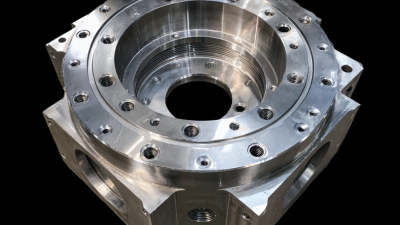

Large CNC machines have revolutionized manufacturing, significantly impacting production costs and time savings. By automating complex cutting and machining processes, these machines reduce the labor intensity associated with traditional manufacturing methods. As a result, businesses can allocate their human resources more efficiently, focusing on tasks that require fine-tuned skills rather than repetitive manual labor. This shift not only lowers labor costs but also enhances overall productivity, allowing companies to scale their operations without a proportional increase in expenses.

Moreover, the precision offered by large CNC machines leads to reduced material waste and faster turnaround times. With advanced software controlling the machining process, manufacturers can achieve tighter tolerances and higher quality finishes, which translates into fewer defects and reworks. This efficiency accelerates the production cycle, enabling companies to meet market demands more swiftly. In industries where time is critical, such as aerospace and automotive, the ability to produce complex components quickly can provide a crucial competitive edge, ultimately fostering greater profitability.

Future Trends: Automation and AI Integration in CNC Machining Technologies

As the CNC machining industry continues to evolve, the integration of automation and artificial intelligence is becoming increasingly pivotal. According to a recent market analysis, the global CNC controller market is projected to expand from approximately $33.67 million in 2025 to an impressive $228.7 million by 2033, registering a steady compound annual growth rate (CAGR) of 2.2%. This growth is largely driven by the increasing demand for high precision and efficient operations across various sectors, highlighting the necessity for advanced machining technologies.

Furthermore, the CNC machining centers market is estimated to grow from $14.35 billion in 2025 to around $21.69 billion by 2033, reflecting a remarkable CAGR of 5.7%. This surge underscores the shift towards smart manufacturing processes, where newer digital manufacturing technologies dramatically enhance productivity. The application of AI in CNC machining not only optimizes operational tasks but also enables machines to adapt and learn from their processes, thereby reducing operational costs and promoting environmental sustainability. The emphasis on technology-driven innovation is central to the future of manufacturing, paving the way for smarter, more efficient production environments.

Related Posts

-

Finding Top Quality Suppliers for the Best Metal CNC Machines

-

Choosing the Right Manufacturer: A Comprehensive Comparison for the Best CNC Metal Products

-

Global Quality Revolution in Best Large Part CNC Machining Made in China

-

Choosing the Right Manufacturer for Best CNC Machine Fabrication Solutions You Can Trust

-

Discover Unmatched Quality in Best CNC Precision Machining from Leading Chinese Manufacturers

-

Unlocking Precision: The Advantages of CNC Metal Machining in Modern Manufacturing

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.