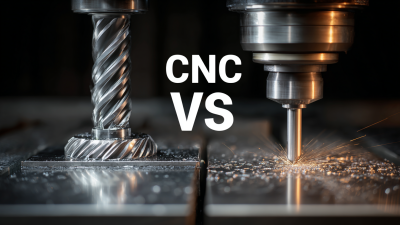

How to Optimize CNC Milling Processes for Maximum Efficiency

In the rapidly evolving landscape of manufacturing, optimizing CNC milling processes has become paramount for companies aiming to enhance productivity and reduce costs. According to a recent report by MarketsandMarkets, the global CNC milling market is projected to reach $6.7 billion by 2025, underscoring the growing reliance on this technology in various industries, from aerospace to automotive. As businesses strive to improve efficiency, the application of advanced strategies in CNC milling can lead to significant reductions in cycle times and waste, ultimately increasing output quality.

By implementing techniques such as adaptive machining, toolpath optimization, and real-time monitoring, manufacturers can achieve maximum efficiency while maintaining precision. This article delves into essential methods for optimizing CNC milling processes, equipping industry professionals with the tools they need to leverage the full potential of their CNC machinery.

Identifying Key Factors in CNC Milling Efficiency

In the quest for maximum efficiency in CNC milling processes, it’s crucial to identify key factors that influence performance. According to a 2021 report by the International Journal of Advanced Manufacturing Technology, optimizing tool path strategies can reduce machining time by up to 30%. Effective tool path management not only enhances material removal rates but also minimizes unnecessary movements, which are often responsible for increased cycle times.

Another critical factor is the choice of cutting tools. A study published by the American Society of Mechanical Engineers highlights that utilizing advanced materials, such as carbide and ceramics, can extend tool life by 50% compared to standard tool materials. This prolongs the intervals between tool changes, significantly improving overall productivity and reducing downtime. Additionally, proper tool selection and maintenance can lead to a decrease in energy consumption, thereby contributing to more sustainable manufacturing practices.

Lastly, machine calibration and regular maintenance play vital roles in CNC milling efficiency. The National Institute of Standards and Technology reported that poorly calibrated machines can lead to a decrease in precision, resulting in an increase in scrap rates by as much as 20%. Implementing routine checks and calibrations ensures that CNC machines operate at peak performance, maintaining both quality and efficiency in the milling process.

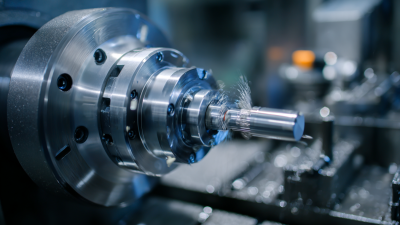

Selecting the Right Tools and Materials for Optimal Performance

When optimizing CNC milling processes, selecting the right tools and materials is paramount for achieving optimal performance. According to a report by the International Organization for Standardization (ISO), using high-quality cutting tools can improve machining efficiency by up to 30%. The right tool material, such as carbide or high-speed steel, can significantly affect the longevity and wear resistance of cutting tools, which translates into reduced downtime and lower overall operational costs. For instance, tools made from carbide can withstand higher temperatures and are more effective in machining hard materials, making them ideal for industries like aerospace and automotive.

In addition to the selection of tools, the choice of materials being machined also plays a crucial role in the efficiency of CNC milling. According to data from the American Society of Mechanical Engineers (ASME), optimizing the workpiece material can reduce machining time by as much as 25%. Materials like aluminum and composites are preferred for their ease of machining and shorter cycle times. Conversely, materials such as stainless steel or titanium, while offering excellent strength-to-weight ratios, may require more advanced tooling and longer processing times. Therefore, a comprehensive understanding of both tools and materials is essential for maximizing efficiency in CNC milling operations.

Implementing Advanced Software Solutions for Process Streamlining

Implementing advanced software solutions can significantly streamline CNC milling processes, enhancing efficiency and productivity. One of the key advancements is the adoption of computer-aided design (CAD) and computer-aided manufacturing (CAM) software. These tools enable precise design alterations, simulation of machining operations, and optimal tool path generation, thereby reducing material waste and minimizing setup times. By automating these phases, manufacturers can focus on refinement rather than repetitive manual processes.

Moreover, integrating enterprise resource planning (ERP) systems with CNC milling software provides a comprehensive approach to manage resources effectively. With real-time data analytics, companies can monitor machine performance and production schedules dynamically. This integration allows for proactive maintenance scheduling, reducing downtime and improving overall operational efficiency. The result is a seamless flow from design to production, minimizing errors and enhancing the capability to respond to market demands quickly. Embracing such technology not only streamlines operations but also positions businesses competitively in a rapidly evolving manufacturing landscape.

Regular Maintenance Practices to Enhance Machine Longevity

Regular maintenance practices are essential for enhancing the longevity of CNC milling machines while optimizing overall efficiency. One of the most critical aspects is the routine inspection of machine components, including bearings, lead screws, and drive motors. By identifying wear and tear early, operators can address issues before they escalate into costly repairs or downtime.

Implementing a structured maintenance schedule not only prolongs the life of the equipment but also ensures consistent performance, reducing the likelihood of unexpected failures during pivotal production periods.

In addition to inspections, lubrication is a vital maintenance practice that should not be overlooked. Proper lubrication of moving parts minimizes friction and heat generation, which can otherwise lead to premature component failure. Utilizing high-quality lubricants and adhering to the manufacturer's recommendations can significantly improve the machine's performance and reliability.

Furthermore, cleaning the machine regularly, including coolant reservoirs and chip removal systems, helps maintain a pristine working environment, reducing the risk of contamination that can negatively impact machining accuracy and surface finish. Together, these maintenance strategies create a robust foundation for maximizing CNC milling efficiency and extending machine life.

Training Operators for Increased Productivity and Safety in CNC Milling

Training operators is a crucial step in optimizing CNC milling processes, as skilled personnel not only enhance productivity but also ensure safety in the workplace. Proper training equips operators with the knowledge to handle machinery efficiently, troubleshoot common issues, and implement best practices on the shop floor. Furthermore, well-trained operators can reduce setup times and decrease machine downtime, significantly boosting overall efficiency.

**Tips: One effective training method is to incorporate hands-on practice alongside theoretical lessons. This approach allows operators to apply what they learn in real-time, reinforcing their skills and confidence. Additionally, encourage continuous learning through workshops and refresher courses, keeping operators updated on the latest CNC technology and techniques.**

Moreover, fostering a culture of safety is essential in CNC milling environments. Operators should be trained to recognize potential hazards and follow safety protocols. Regular safety drills and clear communication about safety measures can help instill a safety-first mindset, reducing the likelihood of accidents and injuries.

**Tips: Always have safety equipment readily available and ensure that operators understand its proper use. Create an open dialogue where employees feel comfortable discussing safety concerns and improvements, which can further enhance a safety-oriented work culture.**

Optimization of CNC Milling Processes: Operator Training Impact

Related Posts

-

Overcoming the Common Challenges in Sourcing the Best CNC Metal Milling Machines

-

Choosing the Right Manufacturer: A Comprehensive Comparison for the Best CNC Metal Products

-

Finding Top Quality Suppliers for the Best Metal CNC Machines

-

How to Overcome Common Challenges in Sourcing the Best CNC Precision Machining Solutions

-

Choosing the Right Manufacturer for Best CNC Machine Fabrication Solutions You Can Trust

-

Discover Unmatched Quality in Best CNC Precision Machining from Leading Chinese Manufacturers

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.