Ultimate Guide to Large Part CNC Machining: Insights and Trends in Precision Manufacturing

In the rapidly evolving landscape of precision manufacturing,

large part CNC machining has emerged as a pivotal technology driving

efficiency and accuracy across various industries. According to a report by Grand View Research, the global

CNC machines market is expected to reach USD 100 billion by 2025, with

a significant portion attributed to the growing demand for large component fabrication in sectors such as

aerospace, automotive, and heavy machinery. As manufacturers strive

to meet increasing production demands while ensuring precision, the significance of large part CNC machining

cannot be overstated. This guide will delve into the latest insights and trends shaping this domain, offering

valuable strategies for optimizing operations and maintaining competitive advantage in an industry defined by

innovation and technological advancement.

In the rapidly evolving landscape of precision manufacturing,

large part CNC machining has emerged as a pivotal technology driving

efficiency and accuracy across various industries. According to a report by Grand View Research, the global

CNC machines market is expected to reach USD 100 billion by 2025, with

a significant portion attributed to the growing demand for large component fabrication in sectors such as

aerospace, automotive, and heavy machinery. As manufacturers strive

to meet increasing production demands while ensuring precision, the significance of large part CNC machining

cannot be overstated. This guide will delve into the latest insights and trends shaping this domain, offering

valuable strategies for optimizing operations and maintaining competitive advantage in an industry defined by

innovation and technological advancement.

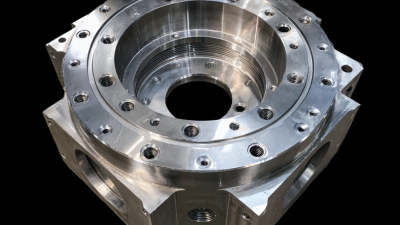

Understanding Large Part CNC Machining: Key Concepts and Techniques

Large part CNC machining is an essential facet of precision manufacturing, enabling the fabrication of complex components with high accuracy and efficiency. Key concepts in this field include the utilization of advanced CNC machines designed to handle larger workpieces, typically exceeding a footprint of 1 meter. According to a report by Markets and Markets, the global CNC machining market is projected to reach $100.8 billion by 2027, with large part machining representing a significant segment of this growth due to increasing demand from industries such as aerospace, automotive, and heavy machinery.

Large part CNC machining is an essential facet of precision manufacturing, enabling the fabrication of complex components with high accuracy and efficiency. Key concepts in this field include the utilization of advanced CNC machines designed to handle larger workpieces, typically exceeding a footprint of 1 meter. According to a report by Markets and Markets, the global CNC machining market is projected to reach $100.8 billion by 2027, with large part machining representing a significant segment of this growth due to increasing demand from industries such as aerospace, automotive, and heavy machinery.

Techniques employed in large part CNC machining include multi-axis machining, which allows for intricate shaping and detailing that would be difficult to achieve with traditional methods. Additionally, the integration of automation and robotic systems in these processes enhances productivity and reduces human error. The 2020 TechSci Research report highlights that the adoption of automation in CNC machining is expected to grow at a CAGR of over 6% through 2025, underlining the industry's shift towards more sophisticated technologies that can handle larger dimensions while maintaining precision. As manufacturers continue to innovate, understanding these key concepts and techniques becomes crucial for staying competitive in a rapidly evolving landscape.

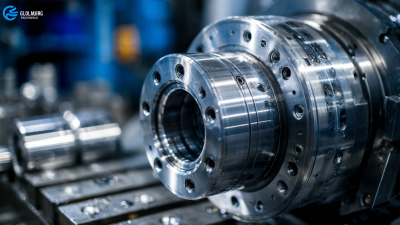

Essential Tools and Equipment for Large Part CNC Machining

In the realm of large part CNC machining, the essential tools and equipment play a crucial role in achieving precision and efficiency. Recent advancements showcase that high precision, automation, and digital technology are pivotal in shaping the future of metalworking. Leading manufacturers are unveiling innovative CNC machinery that leverages these technological advancements, facilitating scalable production of large components. This shift reflects the industry’s growing demand for sophisticated CNC tools and systems that enhance operational efficiency and output quality.

As the CNC vertical machining centers market is projected to grow significantly in the coming years, driven largely by AI-powered enhancements, it becomes clear that the integration of advanced tools is not just beneficial, but necessary. Coupled with the concept of digital twins, which ensures seamless virtual and real-world interactions of machines, manufacturers can optimize machining operations, reducing errors and improving product consistency. Consequently, investing in the right equipment and staying abreast of technological trends can set organizations apart in the competitive landscape of precision manufacturing.

Navigating Material Selection for Large CNC Machining Projects

When embarking on large CNC machining projects, the choice of material is pivotal to achieving precision and efficiency. The nature of the project often dictates the suitable materials, balancing properties such as strength, weight, and machinability. For instance, metals like aluminum and steel are frequently chosen for their durability and adaptability. Aluminum is particularly favored for its lightweight characteristics, making it easier to handle and reducing operational costs. On the other hand, steel offers unparalleled strength, ideal for components that require high resilience under stress.

In addition to metals, various polymers and composite materials are gaining traction in large CNC machining applications. These materials provide benefits like corrosion resistance and reduced weight, making them suitable for industries such as aerospace and automotive. When selecting materials, it's essential to consider not only the physical properties but also the intended use and environmental factors. Collaborating with material experts can further enhance the decision-making process, ensuring the selected material aligns with the desired specifications and manufacturing capabilities.

Trends in Precision Manufacturing: Innovations in Large Part Machining

In recent years, the landscape of precision manufacturing has undergone significant transformation, particularly in the realm of large part CNC machining. Innovations in technology are pushing the boundaries of what’s possible, leading to enhanced efficiency and improved product quality. Advanced CNC machines equipped with multi-axis capabilities allow for intricate designs and tighter tolerances, while automation is streamlining production processes. This shift not only boosts productivity but also reduces lead times, making large part machining more accessible to various industries.

Sustainability has also become a key trend, with manufacturers seeking eco-friendly practices. The integration of additive manufacturing techniques into traditional CNC machining is revolutionizing how components are produced. By minimizing material waste and energy consumption, companies can achieve a more sustainable production cycle.

Furthermore, real-time data analytics and IoT technologies are empowering manufacturers to monitor machinery performance and predict maintenance needs, ultimately driving greater operational efficiency and reliability in large part CNC machining. As these trends continue to evolve, they are reshaping the future of precision manufacturing, making it more innovative and sustainable than ever before.

Best Practices for Quality Control in Large CNC Machining Operations

Quality control in large CNC machining operations is critical for ensuring precision and minimizing waste. According to a report by Market Research Future, the global CNC machining market is expected to reach approximately $100 billion by 2025, with a significant portion attributed to large part machining. This emphasizes the need for rigorous quality control processes, as slight deviations can lead to substantial financial losses. Implementing regular calibration of machines and utilizing advanced inspection technologies, such as laser scanning and coordinate measuring machines (CMM), can enhance accuracy and reliability.

Additionally, adopting industry best practices such as the use of Statistical Process Control (SPC) can significantly impact the quality of output in CNC machining. Data from the American Society for Quality indicates that organizations utilizing SPC methods can reduce process variability by up to 50%, which is essential for large components where precision tolerances are tight. Furthermore, investing in skilled labor and ongoing training in quality management can help maintain high standards and foster a culture of continuous improvement, ultimately leading to better outcomes in large part CNC machining operations.

Related Posts

-

Global Quality Revolution in Best Large Part CNC Machining Made in China

-

Global Market Insights on Best Machining Parts Trends for 2025

-

How to Overcome Common Challenges in Sourcing the Best CNC Precision Machining Solutions

-

Navigating the Future: 2025 Market Insights for Best Precision Machining with Essential Strategies Revealed

-

How to Identify and Select the Best High Precision Machining Suppliers for Your Needs

-

Exploring the 2025 Tech Trends in CNC Metal Machining: Innovations Driving Industry Efficiency

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.