Innovative Solutions for Your Home CNC Machine Investment

Investing in a home CNC machine can open up a world of creative possibilities for DIY enthusiasts, hobbyists, and even professionals seeking to enhance their home workshops. However, as with any technological investment, challenges inevitably arise that can hinder the full potential of these innovative machines. From issues related to calibration and software compatibility to concerns about material handling and maintenance, understanding the common problems associated with home CNC machines is crucial for ensuring a seamless user experience. In this blog, we will explore various innovative solutions designed to address these challenges, helping you maximize the efficiency and effectiveness of your home CNC machine. Whether you're a seasoned user or just starting on your CNC journey, this guide will provide you with valuable insights to navigate the complexities of owning and operating a home CNC machine.

Understanding CNC Machines: A Beginner's Guide to Home Investments

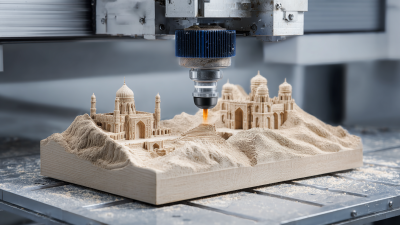

CNC machines are becoming increasingly popular for home use, allowing hobbyists and small business owners to create precise and intricate designs. For beginners, understanding these machines is crucial before making an investment. CNC, or Computer Numerical Control, automates the process of controlling machine tools through a computer program. This automation leads to increased accuracy and efficiency, making it an attractive option for those looking to undertake custom projects.

When considering a CNC machine, it's essential to identify your specific needs. Assess what materials you’ll be working with and the complexity of the projects you have in mind. Tips to keep in mind include researching different types of CNC machines, such as milling machines, routers, and laser cutters, to find one that aligns with your skills and objectives. Additionally, consider the software compatibility of the machine, as user-friendly software can significantly ease the learning curve.

Investing in a CNC machine also entails factoring in ongoing costs. Regular maintenance and the purchase of materials can add up, so it’s wise to budget accordingly. To ensure a more informed decision, start by following CNC machine forums or social media groups. Engaging with other CNC enthusiasts can provide valuable insights and tips that may help guide your investment and enhance your experience as you embark on your CNC journey at home.

Essential Features to Look for When Choosing Your Home CNC Machine

When choosing a home CNC machine, it’s critical to prioritize essential features that align with your project needs and budget. According to a recent report by Research and Markets, the global CNC market is projected to grow significantly, reaching USD 117.93 billion by 2027, indicating a robust interest among hobbyists and professionals alike in adopting CNC technology at home.

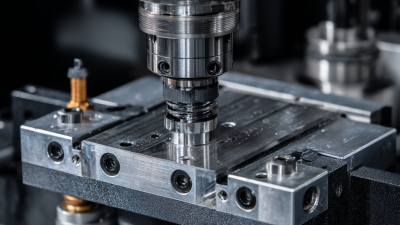

One key feature to consider is the machine's build quality and material compatibility; gaining access to a sturdy machine that can handle various materials—from wood to aluminum—widens your project's potential.

One key feature to consider is the machine's build quality and material compatibility; gaining access to a sturdy machine that can handle various materials—from wood to aluminum—widens your project's potential.

Moreover, software compatibility is crucial. A study by Statista indicates that 37% of home CNC users identify ease of software integration as a top priority. In today's market, look for machines that come equipped with user-friendly interfaces and compatible design software. This ensures that you can easily translate your designs into actionable projects without getting bogged down by complex setups. Overall, focusing on these essential features will help you make a sound investment in a home CNC machine that meets your specific crafting needs and aspirations.

Innovative CNC Software: Enhancing Your DIY Projects with Technology

In today’s rapidly advancing technological landscape, innovative CNC software plays a pivotal role in transforming DIY projects into professional-grade creations. With intuitive interfaces and powerful features, these software solutions enable hobbyists and makers to bring their creative visions to life with ease. From advanced 3D modeling tools to automated machining processes, the right CNC software significantly enhances the design workflow, allowing users to focus on creativity rather than technical limitations.

Moreover, the integration of CNC software with home machines opens up an array of possibilities for personalization and customization. Whether you’re crafting intricate wooden sculptures, designing custom metal parts, or even producing unique gifts, the advanced functionalities of these software can streamline production, ensuring accuracy and consistency. As technology continues to evolve, DIY enthusiasts now have access to resources that not only simplify complex tasks but also inspire innovation and experimentation in their projects. With this powerful software at your fingertips, the potential for creating remarkable pieces of art and functional items is virtually limitless.

Investment in Home CNC Machines: A Trend Analysis

This chart represents the estimated investment in home CNC machines over the past five years, highlighting the increasing trend as more DIY enthusiasts adopt innovative CNC software for their projects.

Maximizing Efficiency: Maintenance Tips for Your Home CNC Setup

When it comes to maintaining your home CNC machine, efficiency is key. Just like the upkeep of a sauna ensures a clean and safe environment, regular maintenance on your CNC setup can significantly enhance its performance and longevity. One of the first steps in maintaining your CNC machine is to keep it clean. Dust and debris can accumulate quickly, affecting both the machine's precision and lifespan. Regularly wiping down surfaces and ensuring that the work area is free of particles will create a better working environment.

Additionally, lubricating moving parts is crucial for seamless operation. Just as saunas require proper treatment of their wood and heating elements to function effectively, your CNC machine benefits from regular application of suitable lubricants. Ensure that you are familiar with the specific requirements of your model and use the recommended lubricants to keep everything running smoothly. Lastly, don’t overlook the importance of checking and calibrating your machine periodically. Regular inspections help catch potential issues before they escalate, ensuring that your investment remains efficient and reliable.

Crafting Unique Creations: Project Ideas for Your CNC Machine Investment

With a CNC machine in your workshop, the possibilities for crafting unique creations are virtually limitless. One exciting project idea is to create personalized home decor items, such as custom signage or intricate wall art. By using your machine to engrave names, quotes, or designs onto wood or metal, you can add a personal touch to any space. These bespoke pieces not only enhance your home but also make for thoughtful gifts that showcase your creativity and craftsmanship.

Another intriguing project to consider is designing functional furniture. Whether it’s a sleek coffee table, a set of shelves, or even a unique chair, CNC machines allow for precise cuts and intricate patterns that can elevate any home furnishing. You can experiment with various materials and finishes to create pieces that reflect your style. Additionally, making furniture at home gives you the luxury of customization, ensuring that each item fits perfectly in your living space and meets your specific needs. Embrace the innovation of CNC technology to transform ordinary materials into extraordinary creations!

Innovative Solutions for Your Home CNC Machine Investment - Crafting Unique Creations

| Project Idea | Material | Estimated Time (Hours) | Skill Level | Cost Estimate ($) |

|---|---|---|---|---|

| Custom Keychains | Acrylic | 2 | Beginner | 15 |

| Wall Art | Wood | 4 | Intermediate | 30 |

| Furniture Design | Plywood | 10 | Advanced | 200 |

| Engraved Gifts | Metal | 3 | Beginner | 25 |

| Toys and Games | MDF | 5 | Intermediate | 50 |

Related Posts

-

Manufacturing Excellence Redefined China Leads the Way with the Best 3D CNC Machines for Global Markets

-

Unveiling the Comprehensive Technical Specifications of the Best Large CNC Machine

-

Finding Top Quality Suppliers for the Best Metal CNC Machines

-

The Future of Precision Engineering: Innovations in Best CNC Parts Production

-

Ultimate Checklist for Achieving the Best Metal Machining Results

-

Unmatched Quality in a Compact Package: The Best Small CNC Milling Machine from Trusted Chinese Manufacturers

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.