Top Strategies for Enhancing Precision Machining Efficiency in Your Manufacturing Process

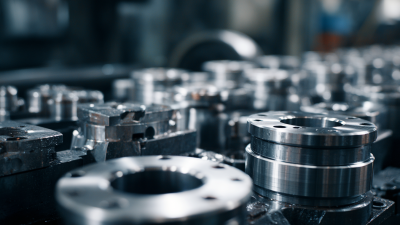

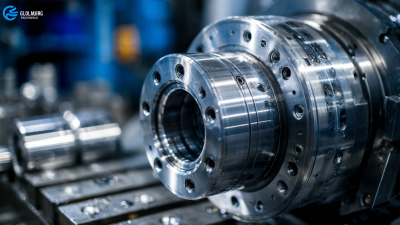

In the competitive landscape of modern manufacturing, enhancing efficiency is crucial for staying ahead, particularly in precision machining operations. Precision machining involves the meticulous process of shaping materials to exact specifications, making it essential for industries that demand high accuracy and reproducibility. As companies strive to improve their productivity and reduce operational costs, identifying and implementing effective strategies becomes paramount. This blog will explore a comparison of various techniques and methodologies designed to boost precision machining efficiency, from advanced technologies and tools to optimized processes and workforce training. By examining these strategies, manufacturers can gain insights into best practices that not only enhance operational efficiency but also ensure quality and consistency in their products.

Strategies for Implementing Advanced CNC Technology to Boost Machining Efficiency

The integration of advanced CNC technology into precision machining processes offers a pathway to significantly enhance manufacturing efficiency. Recent studies highlight that the adoption of digital manufacturing technologies has led to productivity improvements across a wide array of industries. For instance, companies implementing Industry 4.0 technologies have reported efficiency gains of up to 30%, attributed to better machine utilization and reduced downtime through smart maintenance systems.

Furthermore, advancements in machine learning play a critical role in optimizing CNC machining operations. These systems are capable of monitoring tool wear in real-time, allowing for proactive maintenance that minimizes disruptions in the production line. In fact, a survey found that businesses employing AI-driven machining strategies can decrease cycle times by approximately 25% and improve product quality, thereby addressing the dual challenge of enhancing output while ensuring sustainability in manufacturing practices. As the landscape evolves, companies that leverage these advanced technologies stand to gain a competitive edge in the rapidly changing market.

Leveraging Automation and Robotics for Streamlined Precision Machining Processes

In the realm of precision machining, leveraging automation and robotics can significantly enhance efficiency and productivity. By integrating advanced robotics into your manufacturing processes, repeated tasks that traditionally occupy a substantial amount of time can be executed with speed and accuracy. This not only reduces the risk of human error but also helps streamline workflows, allowing skilled workers to focus on more complex aspects of production that require human oversight and creativity.

Additionally, automation tools can optimize machine operations by monitoring processes in real-time and making necessary adjustments on the fly. Smart sensors and data analytics further empower manufacturers to predict maintenance needs and identify inefficiencies before they escalate. Implementing these technologies leads to a more responsive manufacturing environment, ensuring that production schedules are met and resources are used efficiently. As manufacturers continue to embrace these advancements, the result is a robust system that not only enhances precision machining capabilities but also positions businesses for future growth and competitiveness in the market.

Optimizing Tool Selection and Maintenance to Reduce Downtime and Enhance Productivity

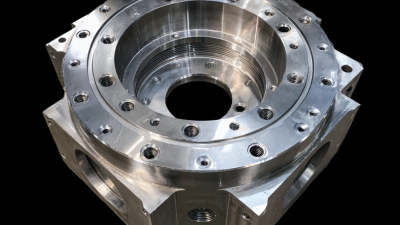

In the world of precision machining, optimizing tool selection and maintenance is vital for reducing downtime and enhancing productivity. A careful approach to choosing the right tools can significantly impact the efficiency of the manufacturing process. Factors such as tool material, geometry, and coating can enhance the cutting performance and extend tool life, ultimately resulting in lower operational costs. Regular assessment of these parameters ensures that machines are equipped with the most effective tools tailored to specific tasks.

Moreover, the maintenance of these tools cannot be overlooked. Implementing a proactive maintenance schedule helps anticipate wear and tear, thereby minimizing unexpected breakdowns. Integrating technology, such as data-driven monitoring systems, can provide insights into tool conditions, allowing for timely replacements and adjustments. This not only elevates production rates but also sustains quality by maintaining consistency in machining processes. Emphasizing both tool selection and maintenance strategies will ensure enhanced efficiency, crucial for staying competitive in the manufacturing industry.

Top Strategies for Enhancing Precision Machining Efficiency in Your Manufacturing Process

| Strategy | Description | Expected Benefits | Frequency of Assessment |

|---|---|---|---|

| Tool Selection Optimization | Choosing the right tools based on material and design specifications. | Improved cutting efficiency and lower tool wear rates. | Monthly |

| Regular Maintenance Schedule | Implementing a maintenance routine for all machining equipment. | Reduced downtime and prolonged equipment life. | Weekly |

| Cutting Parameter Optimization | Adjusting feed rates, speeds, and depths of cut for maximum efficiency. | Enhanced productivity and improved surface finish quality. | Bi-Weekly |

| Employee Training Programs | Regularly training staff on best machining practices and tool usage. | Improved operational efficiency and reduced error rates. | Quarterly |

| Process Monitoring Systems | Implementing real-time monitoring of machining processes. | Immediate detection of issues leading to lower scrap rates. | Continuous |

Data-Driven Decision Making: Utilizing Analytics for Continuous Improvement in Machining Operations

In today's competitive manufacturing landscape, data-driven decision-making is a game changer for enhancing precision machining efficiency. By leveraging advanced analytics, manufacturers can continuously improve their machining operations, turning data into actionable insights. Machine learning algorithms play a pivotal role in this process, allowing companies to evaluate vast amounts of operational data swiftly, identify inefficiencies, and optimize production strategies. This data-centric approach not only streamlines workflow but also significantly reduces costs associated with downtime and material waste.

Moreover, the integration of artificial intelligence into machining operations is rapidly evolving, empowering businesses to make informed decisions in real-time. Automated systems can analyze performance metrics and operational parameters, enabling manufacturers to adapt processes on-the-fly. This synergy between machine learning and real-time data analysis fosters a proactive maintenance culture, ensuring machines operate at peak efficiency while minimizing the risk of unexpected failures. As organizations strive to become data-driven enterprises, embracing these technologies will be vital in staying ahead in the dynamic manufacturing sector.

Sustainable Practices in Precision Machining: Achieving Efficiency While Reducing Waste

Sustainable practices in precision machining have become a focal point in the manufacturing sector, aiming to enhance efficiency while significantly minimizing waste. According to a recent report by the National Institute of Standards and Technology (NIST), manufacturers adopting sustainable strategies can increase their operational efficiency by up to 30%, while simultaneously reducing material waste by as much as 20%. This dual benefit emphasizes the importance of integrating sustainability into your machining processes.

One effective strategy is to implement a closed-loop cooling system, which helps in conserving coolant resources and reduces waste management costs. By recycling the coolant, manufacturers not only save money but also ensure a cleaner production environment. Additionally, regularly monitoring and optimizing cutting tools can decrease tool wear and extend their life, which ultimately leads to lower material consumption and waste.

One effective strategy is to implement a closed-loop cooling system, which helps in conserving coolant resources and reduces waste management costs. By recycling the coolant, manufacturers not only save money but also ensure a cleaner production environment. Additionally, regularly monitoring and optimizing cutting tools can decrease tool wear and extend their life, which ultimately leads to lower material consumption and waste.

Tip: Invest in real-time data monitoring tools to track your machining processes. These tools can provide insights into energy usage and material performance, enabling you to make informed decisions that align with both efficiency and sustainability goals. Another impactful approach is to train your workforce on lean principles, allowing them to identify waste sources and streamline operations, thereby fostering a culture of continuous improvement in precision machining.

Related Posts

-

How to Identify and Select the Best High Precision Machining Suppliers for Your Needs

-

Mastering the Art of Selecting the Best Machining Parts for Your Global Supply Chain

-

Global Market Insights on Best Machining Parts Trends for 2025

-

How to Overcome Common Challenges in Sourcing the Best CNC Precision Machining Solutions

-

Exploring the 2025 Tech Trends in CNC Metal Machining: Innovations Driving Industry Efficiency

-

Global Quality Revolution in Best Large Part CNC Machining Made in China

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.