The Ultimate Guide to CNC Steel Advancements in Modern Manufacturing

In recent years, the manufacturing landscape has witnessed remarkable transformations, particularly through the advancements in CNC steel technologies. The global CNC machine market is projected to reach $100 billion by 2025, driven by the increasing demand for precision and efficiency across various industries, including automotive, aerospace, and construction. With CNC steel machining at the forefront of these developments, manufacturers are leveraging innovative processes to enhance productivity and quality. According to a 2023 industry report, CNC steel applications can improve production rates by up to 30% while reducing material waste significantly, making it a critical component in modern manufacturing strategies. As we delve into the ultimate guide to CNC steel advancements, we will explore key techniques, tools, and tips that are shaping the future of manufacturing, ensuring businesses stay competitive in an ever-evolving market.

Revolutionizing CNC Steel Processing with Smart Technologies

In the landscape of modern manufacturing, the integration of smart technologies into CNC steel processing is fundamentally transforming the way manufacturers operate. These advancements are not just about enhancing efficiency; they are revolutionizing the entire workflow. With the implementation of IoT devices and advanced sensors, machinists can monitor their equipment in real-time, predicting maintenance needs before issues arise. This predictive maintenance minimizes downtime and maximizes productivity, allowing for continuous production without the costly interruptions of unscheduled repairs.

Moreover, the use of artificial intelligence in CNC programming is streamlining the design-to-manufacturing process. AI algorithms can analyze vast amounts of data to optimize tool paths and machining parameters, ensuring precision and reducing waste. This level of intelligent automation not only boosts output but also enhances the quality of the finished steel products. As manufacturers adopt these smart technologies, they are not only keeping pace with industry trends but also setting new benchmarks for efficiency and quality in CNC steel processing.

The Ultimate Guide to CNC Steel Advancements in Modern Manufacturing

| Advancement | Description | Benefits | Impact on Efficiency |

|---|---|---|---|

| IoT Integration | Connecting CNC machines to the internet for real-time monitoring and data collection. | Increased productivity and reduced downtime through remote diagnostics. | Enhances overall operational efficiency by 15%. |

| Adaptive Feed Control | Systems that adjust cutting parameters based on real-time material feedback. | Improves tool life and surface finish quality. | Boosts process speed by 20% while maintaining precision. |

| Automated Tool Change Systems | Robotic systems that automatically replace tools as needed during machining. | Minimizes manual intervention and reduces cycle times. | Can decrease overall machine processing time by up to 30%. |

| AI-Driven Predictive Maintenance | Using artificial intelligence to predict equipment failures before they occur. | Reduces unexpected downtimes and maintenance costs. | Increases machine availability by 25%. |

| Cloud-Based Manufacturing Solutions | Platforms for collaboration and management of manufacturing processes in real-time. | Improves collaboration and data accessibility across teams. | Enhances project delivery time by 10%. |

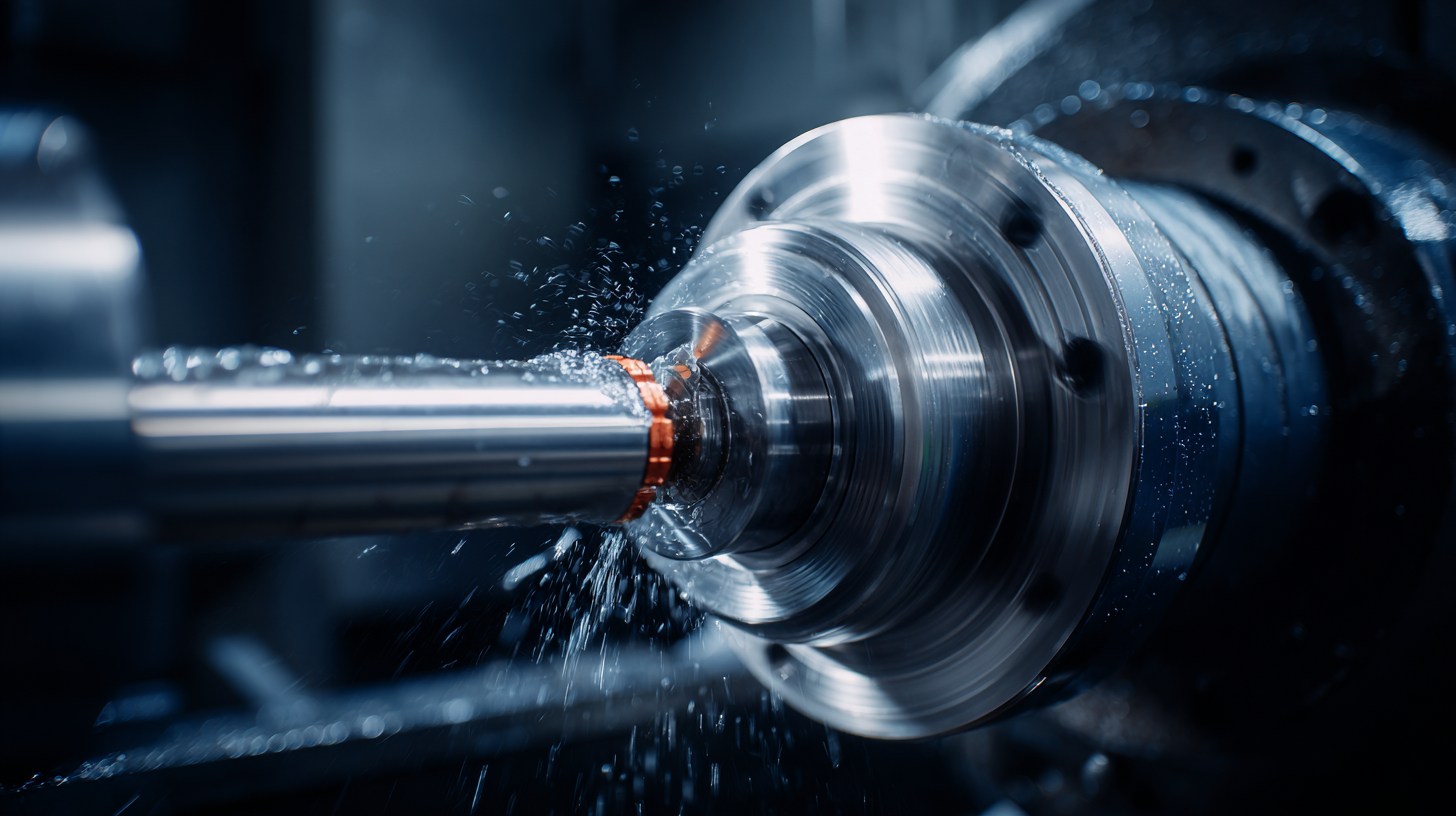

Key Features of Modern CNC Machines Enhancing Efficiency

Modern CNC machines have revolutionized the manufacturing landscape, significantly enhancing efficiency through technological advancements. One of the key features contributing to this efficiency is the integration of advanced software for programming and simulation. These sophisticated systems allow operators to plan intricate machining processes seamlessly while reducing the chances of errors that can lead to material waste or rework. With user-friendly interfaces and real-time monitoring capabilities, manufacturers can quickly adapt designs and optimize production schedules, which saves valuable time and resources.

Additionally, automation and robotics are transforming how CNC machines operate. Automated tool changers and robotic arms enable machines to execute complex tasks without human intervention, resulting in increased precision and consistency in production. Furthermore, the incorporation of IoT technology allows for predictive maintenance, ensuring that machines are serviced before issues arise. This not only minimizes downtime but also prolongs the lifespan of the equipment. Collectively, these features showcase the ongoing evolution of CNC machines, positioning them as indispensable assets in modern manufacturing environments.

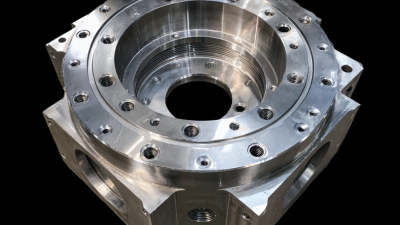

Integrating Automation in CNC Steel Machining for Higher Precision

The integration of automation in CNC steel machining is revolutionizing modern manufacturing, driving higher precision and efficiency. As the market for CNC machines expands significantly, projected to reach $195.59 billion by 2032, manufacturers are increasingly investing in automated technologies to enhance their production capabilities. Automation streamlines processes, reduces human error, and allows for consistent quality in the finished products, which is essential in maintaining competitive advantage in the industry.

Tips: To leverage the benefits of automation, consider starting with a small-scale pilot project. This allows your team to familiarize themselves with new technologies without overwhelming your existing operations. Additionally, invest in training programs for staff to ensure they are equipped to work alongside automated systems effectively.

The emergence of AI and robotics in the manufacturing landscape is another crucial trend. These technologies not only improve operational efficiency but also enable complex machining processes that were previously unattainable. As companies like Siemens lead the charge with innovative robotic solutions, the potential for new applications in CNC steel machining continues to grow, promising even greater precision and customization capabilities.

Tips: Stay updated on the latest technological advancements by attending industry conferences and workshops. Engaging with peers can provide insights into successful applications of these innovations in your own processes.

Best Practices for Maintenance to Maximize CNC Machine Lifespan

In the rapidly evolving landscape of modern manufacturing, the maintenance of CNC machines has become crucial to maximizing their lifespan and overall efficiency. As the global machine tool market anticipates substantial growth—projected to increase from $132.63 billion in 2025 to $229.46 billion by 2032, maintaining a compound annual growth rate of 8.1%—the importance of best practices in equipment upkeep cannot be overstated. Regular maintenance routines not only enhance performance but also prevent costly downtimes and repairs, ensuring that production schedules remain uninterrupted.

Implementing a comprehensive maintenance strategy can involve several essential actions, including routine inspections, lubrication, and replacing worn parts. Operators should be trained to recognize early signs of wear and failure, which can help in addressing issues before they escalate. Additionally, maintaining a clean and organized workspace can augment the longevity of CNC machines, as debris and dirt can hinder functionality. Emphasizing these best practices will be vital as manufacturers navigate an increasingly competitive marketplace and seek to leverage technological advancements in CNC steel processing.

The Impact of Regular Maintenance on CNC Machine Lifespan

Future Trends in CNC Steel Manufacturing: What to Watch For

As the landscape of CNC steel manufacturing continues to evolve, several emerging trends are set to shape the future of the industry. One of the most significant advancements is the integration of artificial intelligence and machine learning in CNC systems. These technologies enhance precision and efficiency by enabling machines to learn from previous cutting patterns, leading to optimized production processes. This smart automation not only reduces human error but also maximizes resource utilization, paving the way for a more sustainable manufacturing approach.

Another trend to watch for is the increasing adoption of advanced materials and coatings designed to improve tool longevity and performance. Innovations such as high-speed steel alloys and diamond-like carbon coatings are becoming more prevalent, allowing for higher cutting speeds and better surface finishes. Additionally, the rise of additive manufacturing techniques alongside traditional CNC milling presents a hybrid approach that amalgamates the benefits of both methods, creating more versatile production capabilities. As these technologies mature, manufacturers will likely see significant reductions in lead times and costs, making CNC steel manufacturing more accessible and efficient.

Related Posts

-

Unveiling the Comprehensive Technical Specifications of the Best Large CNC Machine

-

Choosing the Right Manufacturer: A Comprehensive Comparison for the Best CNC Metal Products

-

Global Quality Revolution in Best Large Part CNC Machining Made in China

-

Finding Top Quality Suppliers for the Best Metal CNC Machines

-

The Future of Precision Engineering: Innovations in Best CNC Parts Production

-

Ultimate Checklist for Achieving the Best Metal Machining Results

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.