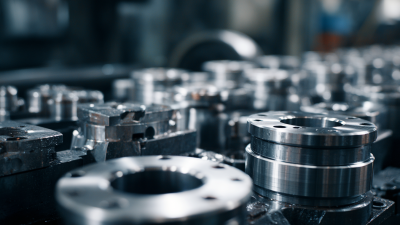

Unlocking Precision: The Advantages of CNC Metal Machining in Modern Manufacturing

In the ever-evolving landscape of modern manufacturing, CNC metal machining stands out as a pivotal technology that drives precision, efficiency, and innovation. According to a report by MarketsandMarkets, the CNC machining market size is expected to reach $100 billion by 2025, growing at a CAGR of 6.5% from 2020. This growth underscores the increasing reliance on CNC metal processes across various industries, from aerospace to automotive. The unparalleled accuracy and repeatability offered by CNC metal machining enable manufacturers to produce complex components with minimal waste, significantly reducing production costs and time. Furthermore, a study by Deloitte highlights that companies leveraging advanced CNC technologies can enhance their operational performance by up to 25%. As we explore the advantages of CNC metal machining, it becomes evident that this technology not only meets the demands of modern manufacturing but also positions organizations for future success in a competitive market.

Exploring CNC Metal Machining: A Comparison with Traditional Manufacturing Techniques

In modern manufacturing, CNC metal machining has emerged as a formidable alternative to traditional methods, offering distinct advantages that cater to today’s demands for efficiency and precision. Unlike manual machining techniques, which rely heavily on the operator's skill and intuition, CNC machining utilizes computer software to automate the entire process. This shift not only enhances accuracy in creating intricate parts but also drastically reduces the likelihood of human error, making CNC an appealing choice for industries where precision is paramount.

Moreover, CNC metal machining is characterized by its remarkable speed and ability to produce complex geometries that would be challenging, if not impossible, to achieve using traditional methods. The automation involved allows for rapid production cycles, so manufacturers can respond swiftly to changing market demands. Additionally, CNC machines can run continuously with minimal supervision, maximizing productivity and minimizing downtime. As companies strive for competitive advantage, the ability to produce high-quality components quickly and efficiently through CNC technology is becoming an essential element of modern manufacturing strategies.

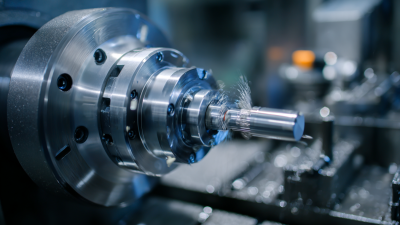

Precision and Accuracy: How CNC Outperforms Conventional Methods in Metalwork

CNC machining stands at the forefront of modern manufacturing, particularly in the metalworking industry, thanks to its unparalleled precision and accuracy. According to a report by MarketsandMarkets, the global CNC machine market size is projected to reach $117.93 billion by 2026, driven by the growing demand for high-quality precision parts. Unlike conventional machining methods, CNC technology utilizes computer-controlled processes that minimize human error, leading to tolerances as tight as ±0.005 inches. This level of accuracy is essential in industries such as aerospace and medical devices, where even the smallest deviation can have significant consequences.

The efficiency of CNC machining also enhances its competitive edge over traditional techniques. A study from The Lincoln Electric Company illustrates that CNC machines can operate continuously for extended periods, significantly reducing cycle times and improving overall productivity. In fact, automated CNC systems can achieve up to 30% higher production rates compared to manual machining. As manufacturers increasingly seek to optimize their operations and maintain quality, CNC machining proves to be an indispensable tool in achieving excellence in metal fabrication. By harnessing advanced technology, businesses can deliver precision-engineered components that meet the rigorous demands of today’s market.

Cost Efficiency in the Long Run: CNC Machining versus Legacy Manufacturing Processes

CNC metal machining has emerged as a pivotal technology in modern manufacturing, particularly when assessing its cost efficiency compared to legacy manufacturing processes. A recent industry report highlights that CNC machining can reduce production time by up to 75%, significantly lowering labor costs and enabling more efficient resource allocation. Moreover, with precise cutting and shaping capabilities, CNC machinery minimizes material waste, which is critical for maintaining competitive pricing in the ever-evolving market landscape.

As industries explore advanced manufacturing techniques, the intersection of CNC machining and emerging technologies like 3D printing represents a substantial opportunity. The mention of titanium's potential in 3D printing hints at a broader trend where traditional and additive manufacturing systems can complement each other. For instance, while 3D printing offers adaptability and complexity in design, CNC machining contributes unparalleled precision and repeatability. Data suggests that by 2025, the additive manufacturing industry is projected to reach a $35 billion valuation, driving the need for more refined and efficient CNC processes to keep pace with this exponential growth. The strategic integration of CNC machining with these innovative practices will be essential for manufacturers aiming to thrive in a competitive and rapidly changing market.

Cost Efficiency in CNC Machining vs. Legacy Manufacturing Processes

This bar chart illustrates the cost efficiency of CNC machining compared to two traditional legacy manufacturing processes. As shown, CNC machining significantly reduces the cost per part, highlighting its advantages in modern manufacturing.

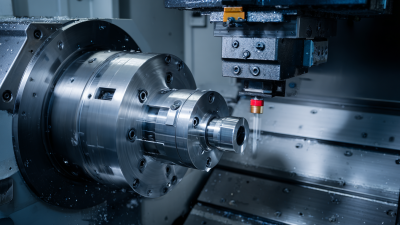

Flexibility and Customization: CNC's Edge Over Other Manufacturing Strategies

CNC metal machining has revolutionized modern manufacturing by offering unparalleled flexibility and customization compared to traditional manufacturing methods. According to a report by MarketsandMarkets, the global CNC machining market is projected to reach $100.4 billion by 2026, growing at a CAGR of 6.7%. This growth is largely driven by the increasing demand for tailored components across various industries, from aerospace to medical devices. CNC machines enable manufacturers to produce intricate designs and modifications rapidly, allowing them to meet specific customer requirements without the lengthy lead times associated with conventional machining techniques.

Additionally, CNC machining's ability to seamlessly integrate design changes into production processes sets it apart from other manufacturing strategies. A study by Technavio highlighted that 34% of manufacturers prioritize customization capabilities when selecting machining solutions. This level of adaptability not only helps businesses respond quickly to market demands but also enhances their competitive edge. By utilizing advanced CNC technologies, manufacturers can optimize production workflows, reduce material waste, and elevate overall efficiency—ultimately ensuring that they remain agile in an ever-evolving market landscape.

Unlocking Precision: The Advantages of CNC Metal Machining in Modern Manufacturing

| Feature | CNC Machining | Traditional Machining |

|---|---|---|

| Flexibility | High - Easily adapts to design changes | Low - Modifications can be time-consuming |

| Customization | Extensive - Custom parts can be produced | Limited - Standard parts with little customization |

| Precision | Very High - Achieves tight tolerances | Moderate - Tolerances can vary |

| Production Speed | Fast - Automated processes increase output | Slow - Manual processes take longer |

| Material Versatility | Broad - Works with various metals and composites | Narrow - Limited to specific materials |

The Future of Manufacturing: Why CNC Metal Machining Is Leading the Industry Evolution

The future of manufacturing is undeniably intertwined with the advancements in

CNC (Computer Numerical Control)

metal machining. As global competition heightens, precision and efficiency have become paramount in the production process.

CNC technology not only allows for intricate designs and high-quality output but also significantly reduces waste and enhances operational speed,

aligning perfectly with the industry's shift towards sustainable practices. The market for CNC machines is projected to rise dramatically,

reflecting the growing demand for innovative manufacturing solutions that can keep pace with the evolving needs of various industries.

Additionally, the metal cutting tools market is expected to experience substantial growth,

driven by the integration of digital manufacturing techniques. Companies are transitioning

from traditional production methods to automated systems that provide better accuracy and lower production costs.

This evolution is vital for manufacturers seeking to improve product quality and meet the increasing demand for high-precision components.

The advancements in CNC metal machining not only represent a leap forward in technology but also pave the way for a more

sustainable and efficient manufacturing landscape.

Related Posts

-

Choosing the Right Manufacturer: A Comprehensive Comparison for the Best CNC Metal Products

-

Discover Unmatched Quality in Best CNC Precision Machining from Leading Chinese Manufacturers

-

How to Overcome Common Challenges in Sourcing the Best CNC Precision Machining Solutions

-

Understanding Common Issues in Precision CNC Machining Processes

-

Unveiling the Comprehensive Technical Specifications of the Best Large CNC Machine

-

Mastering the Art of Selecting the Best Machining Parts for Your Global Supply Chain

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.