What is CNC Machine Fabrication and How Does It Work in Manufacturing

CNC machine fabrication represents a revolutionary shift in the manufacturing landscape, characterized by the automated control of machining tools through computer systems. In recent years, this technology has gained substantial traction, with market research firm MarketsandMarkets forecasting that the global CNC machine market will reach USD 117.14 billion by 2026, growing at a CAGR of 5.3% from 2021. As industries strive for efficiency and precision, understanding the intricacies of CNC machine fabrication becomes imperative for manufacturers looking to remain competitive.

Dr. Emily Hawthorne, a renowned expert in advanced manufacturing technologies, asserts, “CNC machine fabrication enhances productivity and reduces waste, making it a cornerstone of modern manufacturing processes.” Her insights emphasize the importance of CNC technology in optimizing production workflows and enhancing product quality. By utilizing computer-aided design (CAD) and computer-aided manufacturing (CAM) software, manufacturers can significantly streamline their operations, thereby driving innovation and improving overall output.

As we delve into the workings of CNC machine fabrication, we will explore its various applications, benefits, and the essential role it plays in enhancing manufacturing capabilities across different sectors. This investigation will reveal how CNC machine fabrication is not merely a tool, but a vital component of the manufacturing revolution, paving the way for smarter, more efficient production systems.

What is CNC Machine Fabrication: An Overview of the Technology

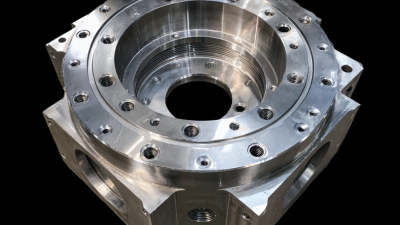

CNC machine fabrication refers to the use of Computer Numerical Control (CNC) technology in the manufacturing process. This advanced method allows operators to automate the control of machine tools through computer programming, significantly enhancing precision and efficiency. CNC machines utilize various tools to cut, shape, and fabricate materials such as metal, plastic, and wood, which makes them essential in various industries, from aerospace to automotive and beyond.

The technology behind CNC machine fabrication is centered around a programming language called G-code. This code directs the machinery on how to execute specific tasks, such as moving to a particular position, and controlling speed and tool changes. The process begins with a CAD (Computer-Aided Design) model, which is then converted into G-code. This seamless connection between design and production not only reduces the margin of error but also accelerates the manufacturing process, allowing for the rapid production of complex parts with a high degree of accuracy. As a result, CNC machine fabrication has become a cornerstone of modern manufacturing, providing companies with the ability to produce components that meet stringent specifications while optimizing resource use.

Key Components of CNC Machines and Their Functions in Manufacturing

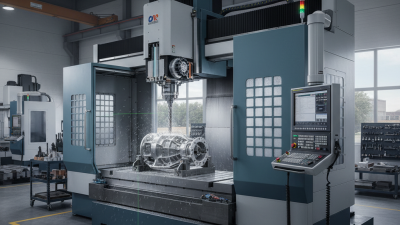

CNC (Computer Numerical Control) machine fabrication represents a transformative approach to manufacturing, heavily reliant on sophisticated machinery and technology. The key components of CNC machines play a vital role in their functionality, each contributing to the precision and efficiency that modern manufacturing demands. Central to a CNC machine is the controller, which interprets a Computer-Aided Design (CAD) file and translates it into commands that the machine can execute. According to the International Federation of Robotics, the use of CNC technology has increased productivity in manufacturing settings by approximately 20%, underscoring its significance in contemporary production workflows.

Another essential component is the drive system, which includes motors and actuators responsible for moving the machine's tools and workpieces with exceptional accuracy. The implementation of servo motors, for instance, allows for high-speed operations and improved repeatability. Data from the 2022 Manufacturing Technology Research report indicates that CNC machines equipped with advanced drive systems can handle tolerances as tight as ±0.001 inches, making them indispensable for industries such as aerospace and medical device manufacturing where precision is critical. The interplay of these components culminates in a streamlined manufacturing process, reflecting the growing trend towards automation and enhanced operational efficiency within various sectors.

The CNC Fabrication Process: Step-by-Step Workflow Explained

CNC machine fabrication is a sophisticated process that transforms raw materials into highly precise parts through computer numerical control. This process involves several key steps, starting with design. Initially, a CAD (Computer-Aided Design) model is created, ensuring that every aspect of the desired component is captured meticulously. Following this, the model is translated into a CNC program, where specific parameters for cutting, milling, or drilling are defined. According to a report by the National Institute of Standards and Technology (NIST), CNC technology has increased manufacturing productivity by up to 30%, showcasing its impact on efficiency and precision in modern fabrication methods.

Once the CNC program is established, the next phase is setup, which includes selecting appropriate tools and fixtures required to hold the material in place during machining. The raw material is then loaded into the CNC machine, where the fabrication process begins. The machine interprets the program and executes the machining operations with remarkable accuracy, often within a tolerance of just a few microns. A report by SME (Society of Manufacturing Engineers) highlights that CNC machines can significantly reduce human error, making them essential in producing high-quality components for industries like aerospace and automotive.

**Tips:** Always ensure that your CAD models are optimized for CNC machining to avoid unnecessary material wastage. Additionally, regular maintenance of CNC machines can enhance their longevity and operational efficiency, reducing unexpected downtime. Lastly, consider the type of material used, as different materials can yield varying results in CNC fabrication, affecting overall productivity.

CNC Machine Fabrication Process: Step-by-Step Workflow

This bar chart illustrates the distribution of time spent in various stages of the CNC fabrication process. It highlights the efficiency of different operations involved in manufacturing using CNC machines.

Impact of CNC Machining on Manufacturing Efficiency and Precision

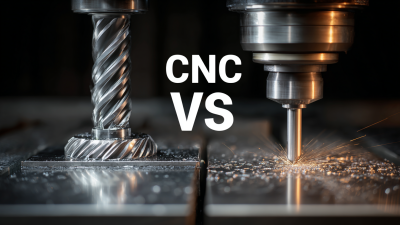

CNC machining has revolutionized the manufacturing landscape by significantly enhancing both efficiency and precision. The technology utilizes computer numerical control to automate tools, allowing for highly accurate cutting, shaping, and finishing of materials. This level of automation eliminates human error and variability inherent in manual machining processes, providing consistent results across production runs. As a result, manufacturers can achieve tighter tolerances and higher-quality outputs, reducing the need for rework and scrap material.

Moreover, CNC machining leads to greater manufacturing efficiency through streamlined operations. The capability to produce complex parts in a single setup minimizes the time spent on secondary operations, thereby accelerating overall production cycles. With the ability to easily program and reprogram machines for different tasks, production schedules can be more flexible, catering to varying customer demands without significant downtime. This adaptability not only helps in optimizing resource allocation but also enhances the competitiveness of manufacturers in the market.

What is CNC Machine Fabrication and How Does It Work in Manufacturing - Impact of CNC Machining on Manufacturing Efficiency and Precision

| Dimension | Data |

|---|---|

| Accuracy | ±0.005 mm |

| Max Cutting Speed | 5000 mm/min |

| Material Compatibility | Metals, Plastics, Wood |

| Typical Lead Time | 1-3 Weeks |

| Production Tolerance | ±0.01 mm |

| Operational Efficiency Improvement | 30-50% |

| Cost Reduction Potential | 20-40% |

| Common Industries | Aerospace, Automotive, Medical |

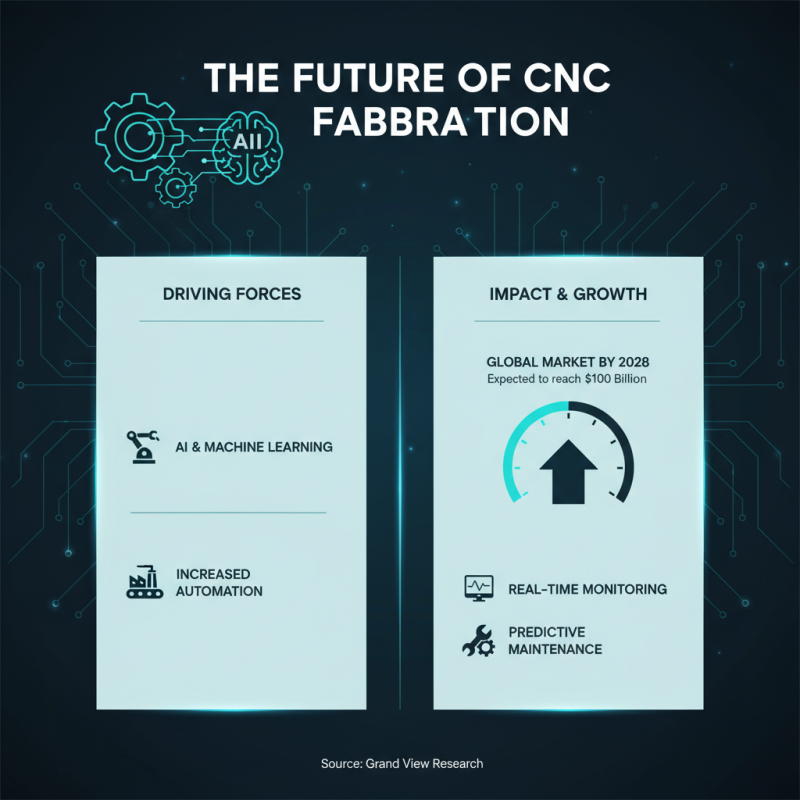

Emerging Trends in CNC Machine Fabrication and Industry Applications

CNC machine fabrication is experiencing rapid advancements as industries strive for enhanced efficiency and precision. One of the emerging trends is the integration of artificial intelligence and machine learning within CNC systems. According to a report by Grand View Research, the global CNC market is expected to reach $100 billion by 2028, driven by increased automation and smart manufacturing processes. These technologies enable real-time monitoring and predictive maintenance, reducing downtime and improving productivity in manufacturing facilities.

Another significant trend is the adoption of sustainable practices in CNC machining. As industries face increasing pressure to reduce carbon footprints, manufacturers are leveraging CNC technology to minimize waste and optimize energy consumption. For instance, a study from the International Journal of Advanced Manufacturing Technology highlights that employing advanced CNC techniques can reduce material waste by up to 30%. Furthermore, manufacturers are now focusing on sourcing eco-friendly materials and implementing recycling strategies to support sustainability goals.

**Tip:** To stay competitive in the evolving landscape of CNC machining, consider investing in dual-axis and multi-axis CNC machines. These machines provide greater flexibility and versatility, enabling manufacturers to handle complex designs with ease while improving production speed. Additionally, regularly upgrading software and training staff on the latest technologies can significantly enhance operational efficiency.

Related Posts

-

Exploring the Top Examples of Large CNC Machines for Global Buyers

-

10 Best Large CNC Machines for Precision Engineering in 2023

-

Top 10 CNC Precision Machining Services to Choose for Your Next Project

-

Global Quality Revolution in Best Large Part CNC Machining Made in China

-

Choosing the Right Manufacturer for Best CNC Machine Fabrication Solutions You Can Trust

-

Choosing the Right Manufacturer: A Comprehensive Comparison for the Best CNC Metal Products

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.