The Ultimate Guide to CNC Steel Advancements in Modern Manufacturing

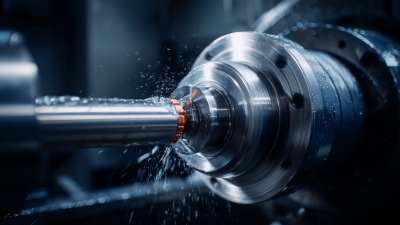

In recent years, the manufacturing landscape has witnessed remarkable transformations, particularly through the advancements in CNC steel technologies. The global CNC machine market is projected to reach $100 billion by 2025, driven by the increasing demand for precision and efficiency across various industries, including automotive, aerospace, and construction. With CNC steel machining at the forefront of these developments, manufacturers are leveraging innovative processes to enhance productivity and quality. According to a 2023 industry report, CNC steel applications can improve production rates by up to 30% while reducing material waste significantly, making it a critical component in modern manufacturing strategies. As we delve into the ultimate guide to CNC steel advancements, we will explore key techniques, tools, and tips that are shaping the future of manufacturing, ensuring businesses stay competitive in an ever-evolving market.

Read more »

By:Samantha - October 14, 2025

By:Samantha - October 14, 2025

How to Choose the Right Machining Parts for Your Project Needs

Choosing the right machining parts for your project is a critical decision that can significantly impact the efficiency, quality, and cost-effectiveness of production. According to a recent market analysis by Industry Research, the global precision machining market is projected to reach $208 billion by 2025, with an annual growth rate of over 6%. This growth underscores the increasing importance of selecting appropriate machining components tailored to specific applications. In today's competitive landscape, understanding the properties, tolerances, and manufacturing processes of machining parts can help engineers and project managers make informed choices that meet performance standards while optimizing resources. Thus, knowing how to choose the right machining parts is not just beneficial; it is essential for achieving project success and maintaining competitiveness in the evolving manufacturing sector.

Read more »

By:Samantha - October 9, 2025

By:Samantha - October 9, 2025

How to Optimize CNC Milling Processes for Maximum Efficiency

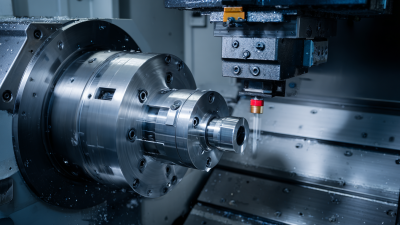

In the rapidly evolving landscape of manufacturing, optimizing CNC milling processes has become paramount for companies aiming to enhance productivity and reduce costs. According to a recent report by MarketsandMarkets, the global CNC milling market is projected to reach $6.7 billion by 2025, underscoring the growing reliance on this technology in various industries, from aerospace to automotive. As businesses strive to improve efficiency, the application of advanced strategies in CNC milling can lead to significant reductions in cycle times and waste, ultimately increasing output quality. By implementing techniques such as adaptive machining, toolpath optimization, and real-time monitoring, manufacturers can achieve maximum efficiency while maintaining precision. This article delves into essential methods for optimizing CNC milling processes, equipping industry professionals with the tools they need to leverage the full potential of their CNC machinery.

Read more »

By:Samantha - October 6, 2025

By:Samantha - October 6, 2025

How to Select the Right CNC Metal Solutions for Your Global Manufacturing Needs

In today's interconnected world, selecting the right CNC metal solutions is crucial for global manufacturing success. As industries continue to evolve and demand for precision and efficiency rises, understanding the various CNC metal offerings has become more important than ever. This guide will explore the key factors to consider when choosing CNC metal solutions that align with your manufacturing needs. From assessing the capabilities of different CNC machines to evaluating the materials and processes involved, making informed decisions can significantly impact your production timeline and product quality. Whether you are a seasoned manufacturer or venturing into CNC metal for the first time, this comprehensive overview aims to equip you with the knowledge necessary to navigate the complexities of CNC technology and optimize your operations on a global scale.

Read more »

By:Lila - October 1, 2025

By:Lila - October 1, 2025

10 Essential Tips for Optimizing CNC Machine Working Efficiency in Your Factory

In today's fast-paced manufacturing landscape, optimizing CNC machine working efficiency is not just a goal but a necessity for staying competitive. According to a report by the International Federation of Robotics, the global demand for CNC machines is projected to grow by over 14% in the next five years, highlighting the critical role these machines play in modern production processes. However, many manufacturers still struggle with maximizing the operational capacity of their CNC equipment, leading to decreased productivity and increased costs. By implementing effective strategies, businesses can enhance their CNC machine working efficiency, ultimately resulting in reduced lead times, improved product quality, and higher profitability. This blog presents ten essential tips that can transform your factory operations and ensure your CNC machines are running at peak performance.

Read more »

By:Lila - September 28, 2025

By:Lila - September 28, 2025

Ultimate Guide to Large Part CNC Machining: Insights and Trends in Precision Manufacturing

In the rapidly evolving landscape of precision manufacturing, large part CNC machining has emerged as a pivotal technology driving efficiency and accuracy across various industries. According to a report by Grand View Research, the global CNC machines market is expected to reach USD 100 billion by 2025, with a significant portion attributed to the growing demand for large component fabrication in sectors such as aerospace, automotive, and heavy machinery. As manufacturers strive to meet increasing production demands while ensuring precision, the significance of large part CNC machining cannot be overstated. This guide will delve into the latest insights and trends shaping this domain, offering valuable strategies for optimizing operations and maintaining competitive advantage in an industry defined by innovation and technological advancement.

Read more »

By:Samantha - September 24, 2025

By:Samantha - September 24, 2025

Addressing High Precision Machining Challenges: Common Issues and Solutions

The demand for high precision machining has surged in recent years, driven by the aerospace, automotive, and medical industries requiring parts with extremely tight tolerances. According to a report by Grand View Research, the global precision machining market is projected to reach $871 billion by 2025, with an annual growth rate of 6.4%. However, manufacturers face numerous challenges, including tooling wear, thermal deformation, and the complexities of material characteristics, that can hinder the production of high-quality components. Addressing these challenges is essential not only for maintaining competitiveness but also for ensuring product reliability and performance in critical applications. This blog will explore common issues encountered in high precision machining and provide actionable solutions to enhance manufacturing processes and outcomes.

Read more »

By:Ethan - September 21, 2025

By:Ethan - September 21, 2025

Understanding CNC Machine Working Principles and Their Applications

The advancement of technology has revolutionized manufacturing processes, with CNC (Computer Numerical Control) machines playing a pivotal role in this transformation. According to a report by Research and Markets, the global CNC machine market is projected to reach USD 117 billion by 2026, with a CAGR of 6.5% from 2021 to 2026. As industries increasingly adopt automation and precision engineering, understanding CNC machine working principles becomes essential for maximizing productivity and enhancing product quality. Despite their advantages, manufacturers often face challenges such as machine malfunction, software issues, and operational inefficiencies. By exploring the intricacies of CNC machine working and their real-world applications, this blog will illuminate the common problems associated with these machines and how they can be effectively mitigated, ensuring a seamless integration of CNC technology in various manufacturing sectors.

Read more »

By:Samantha - September 17, 2025

By:Samantha - September 17, 2025

Exploring the Top Examples of Large CNC Machines for Global Buyers

In the world of modern manufacturing, the emergence of large CNC machines has revolutionized the way industries approach precision engineering and production efficiency. These powerful machines enable manufacturers to create intricate components and large-scale structures with unmatched accuracy and speed. As global markets continue to evolve, the demand for specialized machinery has surged, leading to an array of large CNC machines designed to meet diverse needs across various sectors. This blog explores the top examples of large CNC machines available to buyers worldwide, highlighting their unique benefits, features, and applications. By understanding these machines, potential buyers can make informed decisions that enhance productivity and drive innovation in their operations, ultimately transforming their manufacturing capabilities.

Read more »

By:Samantha - September 10, 2025

By:Samantha - September 10, 2025

Top Strategies for Enhancing Precision Machining Efficiency in Your Manufacturing Process

In the competitive landscape of modern manufacturing, enhancing efficiency is crucial for staying ahead, particularly in precision machining operations. Precision machining involves the meticulous process of shaping materials to exact specifications, making it essential for industries that demand high accuracy and reproducibility. As companies strive to improve their productivity and reduce operational costs, identifying and implementing effective strategies becomes paramount. This blog will explore a comparison of various techniques and methodologies designed to boost precision machining efficiency, from advanced technologies and tools to optimized processes and workforce training. By examining these strategies, manufacturers can gain insights into best practices that not only enhance operational efficiency but also ensure quality and consistency in their products.

Read more »

By:Lila - September 7, 2025

By:Lila - September 7, 2025

Unlocking Precision: The Advantages of CNC Metal Machining in Modern Manufacturing

In the ever-evolving landscape of modern manufacturing, CNC metal machining stands out as a pivotal technology that drives precision, efficiency, and innovation. According to a report by MarketsandMarkets, the CNC machining market size is expected to reach $100 billion by 2025, growing at a CAGR of 6.5% from 2020. This growth underscores the increasing reliance on CNC metal processes across various industries, from aerospace to automotive. The unparalleled accuracy and repeatability offered by CNC metal machining enable manufacturers to produce complex components with minimal waste, significantly reducing production costs and time. Furthermore, a study by Deloitte highlights that companies leveraging advanced CNC technologies can enhance their operational performance by up to 25%. As we explore the advantages of CNC metal machining, it becomes evident that this technology not only meets the demands of modern manufacturing but also positions organizations for future success in a competitive market.

Read more »

By:Samantha - September 3, 2025

By:Samantha - September 3, 2025

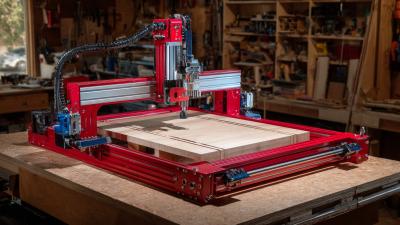

Innovative Solutions for Your Home CNC Machine Investment

Investing in a home CNC machine can open up a world of creative possibilities for DIY enthusiasts, hobbyists, and even professionals seeking to enhance their home workshops. However, as with any technological investment, challenges inevitably arise that can hinder the full potential of these innovative machines. From issues related to calibration and software compatibility to concerns about material handling and maintenance, understanding the common problems associated with home CNC machines is crucial for ensuring a seamless user experience. In this blog, we will explore various innovative solutions designed to address these challenges, helping you maximize the efficiency and effectiveness of your home CNC machine. Whether you're a seasoned user or just starting on your CNC journey, this guide will provide you with valuable insights to navigate the complexities of owning and operating a home CNC machine.

Read more »

By:Lila - August 29, 2025

By:Lila - August 29, 2025

Understanding Common Issues in Precision CNC Machining Processes

In the ever-evolving landscape of manufacturing, precision CNC machining has emerged as a cornerstone for achieving high-quality production standards across various industries. According to a recent report by MarketsandMarkets, the global CNC machining market is expected to reach $100 billion by 2025, driven by increased demand for precision parts in sectors such as aerospace, automotive, and medical devices. Despite its advantages, precision CNC machining processes are not devoid of challenges, including tool wear, machine calibration, and material inconsistencies. Addressing these common issues is crucial for manufacturers aiming to enhance efficiency and reduce production costs. This article will explore the top strategies for overcoming these obstacles and ensuring optimal precision CNC machining outcomes in today’s competitive environment.

Read more »

By:Lila - August 24, 2025

By:Lila - August 24, 2025

Unlocking the Potential of Best Home CNC Machines in Woodworking with Step by Step Applications

In the realm of woodworking, the advent of the home CNC machine has revolutionized the way hobbyists and professionals alike approach their craft. No longer limited to traditional hand tools, woodworkers now have the opportunity to unlock their creativity and achieve precision with the aid of advanced technology. This blog delves into the incredible potential of the best home CNC machines available on the market, showcasing step-by-step applications that elevate woodworking projects from simple to extraordinary. By exploring various examples, we aim to demonstrate not only the versatility of these machines but also how they can enhance the woodworking experience, allowing artisans to transform their visions into reality with unparalleled accuracy and efficiency. Whether you're a seasoned craftsman or a newcomer to the world of woodworking, this comprehensive guide will illuminate the path to harnessing this powerful tool in your workshop.

Read more »

By:Samantha - August 19, 2025

By:Samantha - August 19, 2025

Navigating the Future: 2025 Market Insights for Best Precision Machining with Essential Strategies Revealed

In the rapidly evolving landscape of manufacturing, precision machining stands out as a cornerstone of innovation and efficiency. According to a report by MarketsandMarkets, the global precision machining market is expected to reach USD 143.51 billion by 2025, growing at a CAGR of 7.89%. This growth is driven by the increasing demand for high-quality components in industries such as automotive, aerospace, and medical. As we navigate the challenges presented by a dynamic marketplace, it becomes imperative for companies to adopt strategic approaches that leverage advanced technologies and optimize production processes. In this blog, we will explore essential strategies that can help manufacturers not only keep pace with market trends but also establish a competitive edge in precision machining for 2025 and beyond.

Read more »

By:Samantha - August 14, 2025

By:Samantha - August 14, 2025

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.