Why You Should Invest in a Home CNC Machine for Your DIY Projects

In today’s world, the DIY movement has gained tremendous momentum, empowering individuals to create and innovate like never before. Among the various tools available to hobbyists and professionals alike, a home CNC machine stands out as a game-changer in the realm of creativity and craftsmanship. Whether you're an experienced woodworker, a metal enthusiast, or a budding artist, investing in a home CNC machine can elevate your projects to a whole new level. This versatile equipment enables you to transform your ideas into tangible results with precision and ease.

The benefits of incorporating a home CNC machine into your DIY arsenal are numerous. With its ability to execute complex designs and intricate patterns, this machine not only enhances the quality of your projects but also saves you valuable time and effort. From custom furniture pieces to personalized gifts, the possibilities are virtually endless. Furthermore, the learning curve associated with operating a home CNC machine is increasingly manageable, thanks to abundant online resources and community support. As more individuals embrace the potential of CNC technology, the opportunity for unique creativity expands, inviting more makers to experiment and innovate in their own workshops.

In summary, the decision to invest in a home CNC machine is not merely about acquiring a tool; it’s about unlocking a world of possibilities and taking your DIY projects to unprecedented heights. By equipping yourself with this powerful machine, you'll not only enhance your skills but also indulge in the joy of creating bespoke items that reflect your personal style and vision.

Benefits of Owning a Home CNC Machine for DIY Enthusiasts

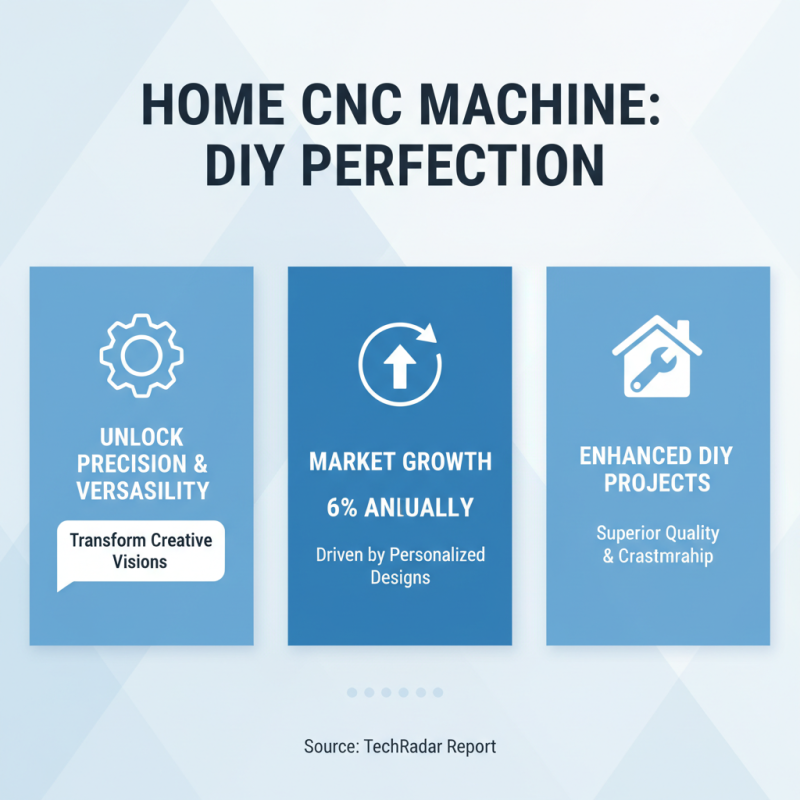

Investing in a home CNC machine opens up a world of possibilities for DIY enthusiasts, empowering them to transform their creative visions into reality. With the growing accessibility of CNC technology, hobbyists can enjoy unparalleled precision and versatility in their projects. A recent report from TechRadar highlights that the CNC machine market is expected to grow by 6% annually, fueled by increased interest in personalized and intricate designs. This means having a home CNC machine can significantly enhance the quality and craftsmanship of DIY projects, leading to better long-term outcomes.

Moreover, owning a home CNC machine can streamline the workflow for projects that require repetitive tasks or intricate designs. For instance, the story of an engineer who took six years to build a 1,000-pixel display underscores the potential of CNC machines in achieving complex outcomes, even if the practicality of the project is debated. Such machines allow enthusiasts to produce precise cuts and engravings, enabling them to tackle ambitious projects with ease. According to a survey by the Fabricators & Manufacturers Association, about 65% of makers reported that using CNC technology enhanced their productivity and creative output, showcasing the benefits of investing in this technology for any DIY enthusiast.

Key Features to Consider When Choosing a CNC Machine

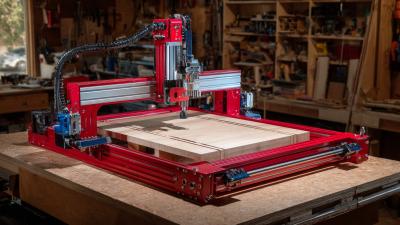

When choosing a home CNC machine for DIY projects, there are several key features to consider to ensure that you are making an informed investment. First and foremost, the machine’s precision is crucial; it should offer high accuracy to create intricate designs and parts. Look for a device that supports multiple materials such as wood, metal, and plastic, which increases versatility for various projects. Additionally, the maximum cutting area is a significant factor, as it determines the size of the projects you can tackle.

Another important aspect is the software compatibility. A user-friendly interface and support for popular CAD/CAM software can significantly enhance your experience, especially if you are new to CNC machining. Furthermore, consider the build quality and reliability of the machine. A sturdy construction aids in better performance and longevity, making it a worthwhile investment. Lastly, don’t overlook customer support and community resources, such as forums or tutorials, which can aid you in resolving issues during your learning process. These features collectively empower you to maximize the potential of your home CNC machine for all your DIY endeavors.

Benefits of Investing in a Home CNC Machine for DIY Projects

Popular Materials You Can Work With Using CNC Technology

CNC (Computer Numerical Control) machines have revolutionized the DIY landscape, enabling hobbyists and artisans to create precision-crafted products with a range of materials. According to a report by IBISWorld, the home CNC machine market has seen a significant growth rate of 8.3% annually from 2018 to 2023, indicating a rising interest in these versatile tools. The capability to work with various materials expands the potential of any DIY project, allowing creators to experiment and innovate.

When it comes to materials, wood remains the most popular choice among CNC users due to its accessibility and ease of manipulation. Hardwood and softwood can be intricately cut and shaped, lending themselves well to furniture making and decorative items. Metalworking is also on the rise; industry data from TechSci Research highlights that the CNC metalworking market is expected to reach $4.1 billion by 2025, showcasing the growing trend of metal projects in home workshops. Additionally, the application of CNC technology in plastics, such as acrylics and PVC, allows creators to produce custom signs and housings, enhancing the aesthetic appeal of DIY ventures. With the increasing affordability of CNC machines and the variety of materials they can handle, there has never been a better time to invest in this technology for your home workshop.

Essential Software and Tools for Effective CNC Operation

Investing in a home CNC machine can significantly enhance your DIY projects, but to fully leverage its potential, you need essential software and tools. A key component in this setup is the post processor, which acts as a bridge between your CAD/CAM software and CNC machine. Understanding what post processors are and how to effectively utilize them with platforms like Fusion 360 is crucial. They translate the design into specific machine instructions, ensuring accurate machining and maximizing efficiency.

In addition to post processors, having simulation software is vital for optimizing CNC operations. Recent advancements in simulation technology offer speed and accuracy, enabling users to preview toolpaths before actual machining. This capability helps identify potential issues and refine processes, thus minimizing waste and enhancing productivity. As the CNC landscape continues to evolve, integrating robust software solutions into your DIY projects not only simplifies the operation but also elevates the quality of your results.

Tips for Maintaining and Optimizing Your Home CNC Machine

Maintaining and optimizing your home CNC machine is crucial for achieving the best results in your DIY projects. One of the most effective ways to ensure optimal performance is through regular cleaning, which helps prevent dust and debris from accumulating in critical areas. Regularly cleaning components such as the spindle, tools, and work area not only prolongs the life of your machine but also ensures precise cutting and engraving. Utilizing appropriate cleaning agents and methods tailored to your machine’s materials will enhance its performance significantly.

Furthermore, consider implementing preventive maintenance routines to keep your CNC machine in peak condition. Regularly lubricating moving parts and checking for any signs of wear and tear can prevent costly repairs down the line. Additionally, calibrating your machine frequently will ensure that it operates at the highest precision. By investing time in maintenance and optimization, you can enhance the reliability of your CNC machine and make the most out of your DIY projects.

Why You Should Invest in a Home CNC Machine for Your DIY Projects - Tips for Maintaining and Optimizing Your Home CNC Machine

| Feature | Description | Maintenance Tips | Optimization Tips |

|---|---|---|---|

| Precision | CNC machines offer high precision for intricate designs. | Regularly calibrate the machine for accurate results. | Use appropriate feeds and speeds for materials. |

| Versatility | Suitable for wood, plastic, and metal materials. | Keep tools clean and replace dull bits. | Experiment with different tooling and software options. |

| Cost-Effectiveness | Saves money on custom parts and prototypes. | Regularly check and tighten loose components. | Utilize software to streamline designs before cutting. |

| Speed | Faster production compared to traditional methods. | Ensure proper lubrication on moving parts. | Optimize cutting paths in the software. |

| Learning Curve | Requires time to master CAD/CAM software. | Take time to read manuals and watch tutorials. | Practice regularly to build confidence and skills. |

Related Posts

-

Unveiling the Comprehensive Technical Specifications of the Best Large CNC Machine

-

Navigating the Challenges of Choosing the Best Home CNC Machine: Insights and Solutions

-

Unlocking the Potential of Best Home CNC Machines in Woodworking with Step by Step Applications

-

The Future of Precision Engineering: Innovations in Best CNC Parts Production

-

Ultimate Checklist for Achieving the Best Metal Machining Results

-

Navigating the Future: 2025 Market Insights for Best Precision Machining with Essential Strategies Revealed

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.